This step by step procedure for changing the gear oil in your rear differential works for a Lexus GX470, FJ Cruiser, 4Runner and most modern Toyota trucks.

The gear oil in your truck keeps friction to a minimum and ensures the long life of your differential gears. Proper maintenance by changing the differential oil is simple and keeps your off-road truck working as designed and saves money. Changing the differential oil yourself allows you to learn a little more about your overland vehicle (you never know when hat knowledge will come in handy on the trail).

The first big decision is what oil to use. It is important to consult your owners manual. Toyota lists the quantity, type and viscosity of oil required. For our 2008 Lexus GX470 the manual lists:

- Capacity: 3.3 quarts

- Type: Hypoid gear oil APL GL-5

- Viscosity: SAE 80w-90

Other item to pick up before you start include new drain and fill plug gaskets. Unless your on the trail working a field repair, don’t try save a few pennies by reusing these little items. (Get a complete set of differential and transfer case gaskets they will also fit your FJ Cruiser and 4Runner)

Most back yard mechanics will have the tools required to perform this simple activity. The tools you will need include:

- 24mm socket and socket wrench

- Torque wrench

- Funnel with flexible tube (Hopkins FloTool 10704 Spill Saver Measu-Funnel)

- Shop rags

- Oil catch pan (Blitz 11837 10 Quart Oil Drain)

- Nitrile or latex gloves (this is a messy job)

Start by placing your GX470 on flat level ground to ensure good draining and proper refill. Tip: clean the axle housing with soapy water and a scrub brush to remove the road and trail gunk. This will prevent any dirt from falling in to the differential while changing the oil.

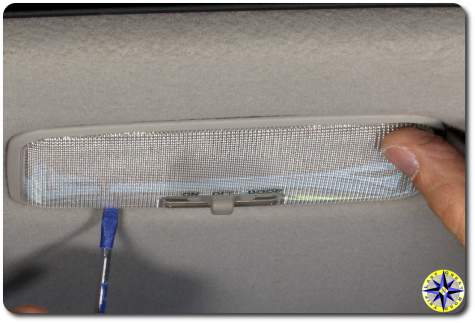

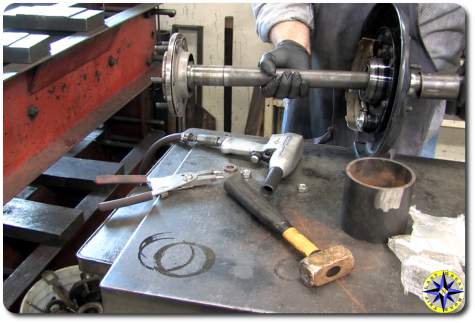

Remove the fill plug using a 24mm socket . The fill plug located in the middle(ish) of the rear axle housing. By removing the fill plug first the housing you ensure you can refill the differential before draining all the oil out.

With the oil catch pan in place remove the drain plug, located on the bottom of the rear axle housing, using a 24mm socket. If your going to use gloves, this is the time to wear them.

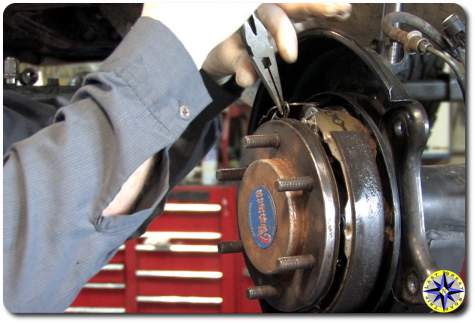

The drain plug has a magnetic insert designed to attract and hold tiny metal shavings that become suspended in the oil. Yes these are little bits of your gears. Inspect the drain plug checking for any chunks and observe how much has accumulated. This will give you an idea of what has been going on inside your differential.

While the oil completely drains, grab the shop rags and clean the fill and drain plugs, removing all the gunk and accumulated metal shavings. When your done the plugs should be clean and dry. Don’t forget which is which.

After the oil is fully drained, wipe the area clean and re-insert the drain plug with a new gasket and hand tighten. Remember the drain plug has the magnetic insert. Now set your torque wrench and tighten down the drain plug. Toyota states the torque specifications for both the drain and fill plugs as 36 foot pounds for our 2008 Lexus GX470. This torque setting is the same for the Toyota FJ Cruiser and 4Runner.

Remember that funnel with flexible tube? Getting the oil out of the bottle or can and into the axle housing through that little hole can be tricky. One of the advantages of the Hopkins FloTool 10704 Spill Saver Measu-Funnel is that the flexible tube funnel cap will screw directly on to some quart bottles. Another tip is to place the unopened gear oil containers in some hot water for five to ten minutes. This will warm up the thick gear lube and allow it to flow more easily.

Squeezing out three plus quarts of thick 90 weight through the tube and into the axle housing will take awhile so get comfortable.

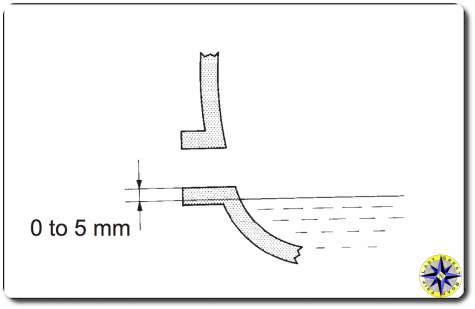

Checking the fill level on flat ground is easy. The oil should barely begin to run out or just about to run out (within 5mm of the fill opening).

Hand tighten the fill plug and new gasket followed by torquing down the plug to Toyota specifications.

Wipe down the housing and check for leaks. Drive around the block a couple of times and check for drips when the test drive is complete.

Like all trucks your Toyota or Lexus requires the differential oil to be changed in order to keep the gears turning smoothly. Changing the rear differential oil on a GX470 (or FJ Cruiser, or 4Runner) is a simple maintenance job anyone can do with a little know how and about 60 minutes.